What you need to know about vertical mushroom farming

You’ve probably seen those expensive mushrooms at the grocery store and wondered if you could grow them yourself. Here’s the thing: mushroom towers let you produce 6.5 to 10 kilograms per square meter weekly—that’s 14-22 pounds (6.5-10 kg/m²) of fresh mushrooms in a space smaller than your kitchen table.

What you need to know about mushroom tower systems

When you’re starting with mushroom towers, you’re basically stacking your growing space vertically instead of spreading it horizontally. These vertical cultivation structures use wire mesh or specialized containers filled with substrate where mushrooms grow out the sides. You’ll get 2-4 times more mushrooms from the same floor space compared to traditional methods.

The science is simple: mushrooms don’t need soil—they need organic matter, moisture, and the right environment. Tower systems give you all three while maximizing your growing area. Modern indoor facilities can produce 12,000 pounds (5,443 kg) monthly using these configurations.

Types of mushroom towers you can build

Outdoor straw towers work great for beginners. You’ll need hog wire fencing, fresh hardwood chips, and mushroom spawn. These towers need partial shade and protection from direct sun. Rain actually helps—it provides natural irrigation.

Indoor controlled towers give you year-round production. You control temperature, humidity, and air circulation precisely. Yes, they cost more upfront, but you’ll harvest mushrooms every week regardless of weather.

Smart automated systems use IoT sensors and AI to monitor growing conditions. They track temperature, humidity, CO2 levels, and moisture content in real-time. Fancy? Sure. But they can double your yields.

How you prepare substrates for mushroom towers

Your substrate choice determines your success. Different mushroom species need different materials. For shiitake (Lentinula edodes), mix 1 kilogram hardwood sawdust with 250 grams wheat bran and 1.6 liters water. Oyster mushrooms (Pleurotus species) aren’t picky—they’ll grow on straw, sawdust, or fresh wood chips.

Why you must sterilize your substrate

Here’s what kills most beginner grows: contamination. You need to sterilize or pasteurize your substrate to eliminate competing organisms. Boil your materials for 5-10 minutes or pressure cook them. Skip this step and you’ll grow mold instead of mushrooms.

The squeeze test tells you if moisture levels are right. Grab a handful of substrate and squeeze hard. You want just a few drops of water—not a stream, not bone dry. Too wet? You’ll get contamination. Too dry? Your mycelium won’t colonize properly.

Safety Warning

- Never eat wild mushrooms without 100% positive identification

- Some mushrooms have toxic look-alikes that can be fatal

- Join your local mycological society for proper training

- When in doubt, throw it out

What environmental conditions your mushroom towers need

Temperature control makes or breaks your operation. Oyster mushrooms need 75°F (24°C) during colonization, then 64°F (18°C) for fruiting. Shiitake prefers 77°F (25°C) for spawn run and 61°F (16°C) to fruit. Stay within ±3.6°F (±2°C) of these targets.

Evaporative cooling systems can drop your temperature by 9°F (5°C) while raising humidity by 10%. That’s often all you need for perfect growing conditions.

How to manage humidity and air flow

You need 80-95% humidity, but here’s the trick: you also need fresh air. Mushrooms breathe oxygen and release CO2, just like us. Without proper ventilation, they’ll grow long stems with tiny caps—what growers call “fuzzy feet.”

Aim for 3-5 complete air changes per hour. During colonization, CO2 levels can reach 5,000-8,000 parts per million (ppm). But when fruiting starts, drop that to 800-1,200 ppm. Professional operations use specialized nozzles and ductwork to ensure even air distribution.

How you build mushroom towers step by step

Start with basic materials: food-grade wire mesh with 4-6 inch (10-15 cm) openings, organic substrate, mushroom spawn, and support structures. Budget $200-500 for a small system or $10,000-30,000 for commercial automation.

Your tower construction process

- Form a circular wire enclosure 3-4 feet (0.9-1.2 m) in diameter

- Place cardboard at the base to block soil fungi

- Add 6 inches (15 cm) of moistened substrate

- Sprinkle spawn at 1:5 ratio (1 part spawn to 5 parts substrate by weight)

- Repeat layers until tower reaches 4-5 feet (1.2-1.5 m) tall

- Top with plastic to retain moisture during colonization

For indoor systems, integrate sensors that monitor conditions 24/7. Wireless networks using machine learning algorithms predict optimal irrigation timing and environmental adjustments.

Which mushroom varieties work best in towers

Not all mushrooms suit vertical growing. Here’s what actually works:

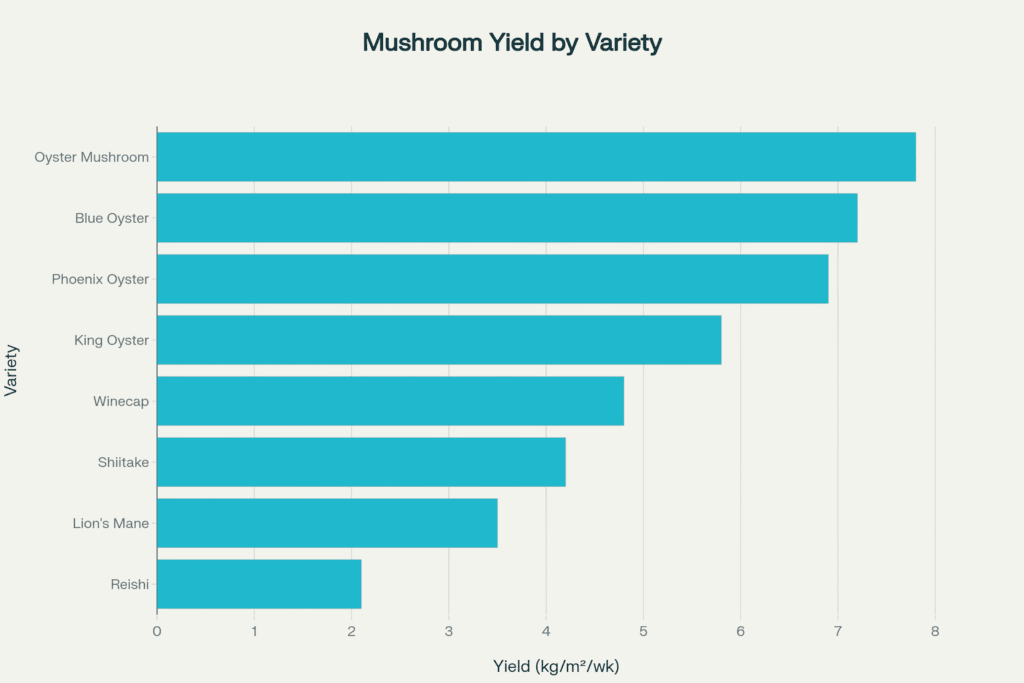

Oyster mushrooms (Pleurotus ostreatus) remain the champions of tower cultivation. You’ll harvest 7.8 kg per square meter weekly (1.6 lbs/sq ft). Blue oysters yield 7.2 kg/m²/week, phoenix oysters produce 6.9 kg/m²/week. They tolerate temperature swings and grow on almost anything organic.

Shiitake mushrooms (Lentinula edodes) take longer—45 days per cycle—but command $25 per kilogram ($11.34/lb) at market. They yield 4.2 kg/m²/week on hardwood substrates. Keep log temperatures at 72-77°F (22-25°C) for best results.

Specialty mushrooms for premium markets

Lion’s mane (Hericium erinaceus) looks like a white waterfall and tastes like seafood. You’ll get 3.5 kg/m²/week at 90% humidity, but they sell for $35 per kilogram ($15.88/lb).

King oyster (Pleurotus eryngii) produces thick, meaty stems perfect for slicing. Expect 5.8 kg/m²/week on straw supplemented with nitrogen. Wine cap (Stropharia rugosoannulata) thrives outdoors, yielding 4.8 kg/m²/week at $20 per kilogram ($9.07/lb).

Equipment and infrastructure you’ll need

Your infrastructure investment depends on scale and automation level. Small operations need $2,500 for basic towers, while large commercial systems require $25,000 just for structures.

Climate control breaks down like this:

- Temperature regulation: $3,000-45,000

- Ventilation equipment: $1,500-18,000

- Humidity control: $800-8,000

- Monitoring sensors: $600-8,000

Advanced robotic systems reduce labor by 60-70%. They handle substrate prep, inoculation, and harvesting, cutting labor hours from 45 to 15 per 100kg production.

Setting up monitoring and automation

Modern towers use comprehensive sensor networks tracking every environmental parameter. IoT-enabled sensors provide real-time data and automated adjustments. You’re looking at $600-8,000 for monitoring equipment, depending on sophistication.

Start simple with basic temperature/humidity sensors, then upgrade as you grow. Even basic automation beats manual monitoring every time.

Why mushroom towers make economic sense

Initial investments range from $10,000-150,000 depending on your goals. Small operations generating $48,400 annually achieve 30% profit margins. Medium and large facilities see margins exceeding 150% with proper management.

The global mushroom market hit $18.74 billion in 2024 and projects growth to $25.41 billion by 2030. You can sell button mushrooms for $1.65/kg, while specialty varieties command premium prices.

Understanding your operational costs

Annual expenses include:

- Substrate materials: $300-4,000

- Spawn inoculation: $200-3,000

- Labor: $1,000-12,000

- Energy for climate control: varies by region

Tower systems achieve 12.8 kg/m² space efficiency versus 3.2 kg/m² for horizontal growing. Water usage drops from 4.5 L/kg to 1.2 L/kg with advanced technology. Those numbers translate directly to your bottom line.

How to troubleshoot common mushroom tower problems

Contamination kills more mushroom grows than any other factor. Healthy mycelium looks white and smells fresh. Brown, black, green, orange, or pink colors mean contamination. Remove affected areas immediately—don’t wait.

Maintain sterile conditions with 70% isopropyl alcohol on all tools and surfaces. One contaminated batch can spread spores throughout your operation.

Managing environmental issues

Moisture problems show up fast. Too dry? Mushrooms crack and shrivel. Too wet? Bacterial blotch appears as slimy brown spots. Aim for that perfect balance—moist but not dripping.

CO2 buildup causes “fuzzy feet”—long stems with underdeveloped caps. Increase ventilation immediately. Light deficiency creates similar symptoms, so provide 12 hours of reading-level light daily.

Wrong spawn ratios wreck yields. Use 20% spawn to 80% substrate by weight for most species. Less spawn means slower colonization and contamination risk. More spawn wastes money without improving yields.

How mushroom towers support sustainability

Mushroom production uses just 1.8 gallons water per pound (15 liters/kg) compared to much higher requirements for other proteins. You’re recycling agricultural waste—straw, sawdust, coffee grounds—into food.

The carbon footprint stays minimal. Mushroom farming produces lower greenhouse gas emissions than crops, fruits, or animal proteins. Energy use ranges from 1.2-2.1 kWh per kilogram depending on system sophistication.

Creating circular economy systems

Every kilogram of mushrooms produces three kilograms of compostable organic matter. This spent substrate enriches garden soil, supports microalgae cultivation, and treats wastewater.

Integrate mushroom towers with other agricultural systems. Use spent substrate for soil improvement, supporting biodiversity while creating valuable secondary products.

What’s next for mushroom tower technology

AI-powered systems now optimize growing conditions through predictive analytics. Machine learning algorithms analyze cultivation data, identifying optimal parameters and predicting harvest timing.

Biotechnology advances create disease-resistant strains with enhanced yields. These innovations expand cultivation possibilities in varying climates while improving economic viability.

Meeting market demands

Consumer preferences favor sustainably produced foods. Rising vegetarian and vegan populations drive demand for mushroom-based proteins. Medicinal mushroom supplements represent the fastest-growing market segment.

Urban agriculture loves mushroom towers. Minimal space requirements and controlled environments make them perfect for city farming. You’re looking at local food security with reduced transportation costs.

Frequently asked questions about mushroom tower cultivation

Q: How much space do I need to start mushroom tower cultivation? A: You can start with as little as 20 square feet (1.9 m²) for a small tower system. Commercial operations typically need 200-1,600 square meters (2,150-17,200 sq ft) for profitable production.

Q: What’s the average yield from mushroom towers compared to traditional growing? A: Tower systems produce 6.5-10+ kg per square meter weekly, while traditional horizontal methods yield 2-3 kg/m²/week. That’s 2-4 times more mushrooms from the same floor space.

Q: How long before I see my first mushroom harvest? A: Oyster mushrooms fruit in 10-14 days after inoculation. Shiitake takes 45-60 days. Most varieties produce multiple flushes over 2-3 months.

Q: What’s the minimum investment for a profitable mushroom tower operation? A: Small profitable operations start around $10,000-15,000 initial investment. You’ll need $200-500 for a hobby system, or $25,000+ for automated commercial production.

Q: Which mushroom variety offers the best return on investment? A: Oyster mushrooms provide the best ROI for beginners—high yields (7.8 kg/m²/week) and moderate prices. Specialty varieties like lion’s mane offer higher prices ($35/kg) but lower yields (3.5 kg/m²/week).

Helpful resources for vertical mushroom farming

- North American Mycological Association (NAMA)

- Mushroom Growers Association

- International Society for Mushroom Science

- Urban Agriculture Network

- “The Mushroom Cultivator” by Paul Stamets and J.S. Chilton

- “Organic Mushroom Farming and Mycoremediation” by Tradd Cotter

- Vertical Farming Institute

Now you understand mushroom tower basics. You’ll succeed faster if you start small with oyster mushrooms and expand as you gain experience.

Your next step: Build a test tower with locally available substrates and document your results